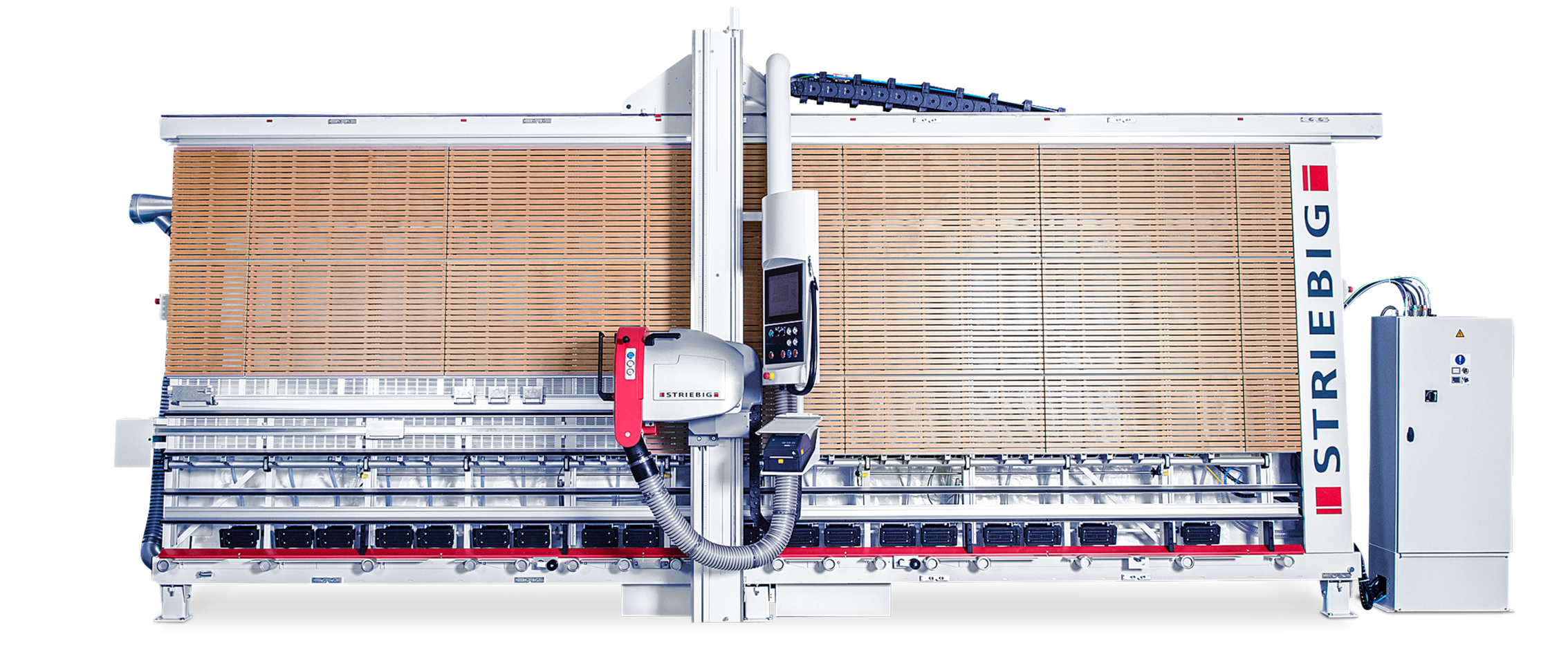

CONTROL – cutting technology meets ergonomics and intelligence

The CONTROL is already well-equipped when it leaves the factory. A 12" touch screen computer and the modern machine software ensure perfect operating comfort in every detail. The automatic saw swivelling is just one of the many functions that make panel cutting ergonomic and comfortable. Intelligent options allow you to achieve a high degree of automation of the sawing process and to integrate CONTROL into the operational data flow.

STRIEBIG CONTROL with ExpertCut (video)

Highlights of the STRIEBIG CONTROL

Cutting technology meets the future

The CONTROL defines the premium class for vertical sawing technology through a high degree of sawing process automation and innovative equipment options. The intelligent visualisation on the clearly arranged 12" touch screen computer guides you safely step by step through the cutting process.

Modern STRIEBIG operating unit (HMI)

With the logically designed user interface, you can control the CONTROL easily and conveniently via a 12" touch screen.

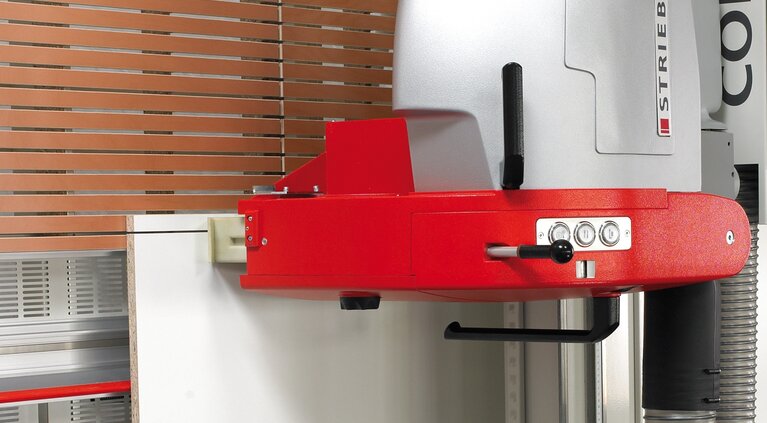

Electronic positioning system EPS-Y and ABO – top trimming

Thanks to the standard EPS-Y you can automatically position the saw unit for horizontal sawing. The ABO, which is also a standard feature, ensures the automatic top trimming cut.

4SB – lower trimming

With this option, the lower trimming cuts are performed automatically. The turning of the panel material and the heavy physical work associated with it is no longer necessary.

The vertical premium class

The CONTROL is already well-equipped when it leaves the factory. A wide range of extensive options allows you to adapt them even further to your needs. Put your CONTROL together in our configurator and benefit from made to measure vertical sawing technology.

Comprehensive standard equipment

- 12" inch touch screen computer with optimal user guidance

- Laser-supported display of the horizontal cut

- Digital measuring system DMS-X

- Electronic positioning system EPS-Y incl. automatic top trimming cut ABO

- Automatic saw beam locking with interface recognition

- Automatic locking and swivelling of the sawing unit

- Automatic insertion and removal of the sawing unit

- Automatic panel end recognition

- Fully automatic sawing sequence

- Selectable sawing cycle

- Pneumatic clutch for easy changeover to manual operation

- Operating time counter

- Tool database

- ALU centre support over the entire machine length

- Integrated, particularly powerful TRK dust extraction. Dust limit value around 1 mg/m³

- Super-silent noise insulation

- Network connection

- UPS 24VDC for Touch-PC (uninterruptible power supply)

- ProLock easy-fix tool clamping system

- Automatic saw beam positioning ASP

| Weight of the saw | approx. 1.200 kg |

| Cutting depth | 80 mm *1 |

| Saw motor power | 5.5 kW (7.5 HP) |

| Saw blade diameter | 300 mm |

| Saw blade bore | 30 mm *2 |

| Emission sound pressure level at the workplace LpA | 83 dB *3 |

| Saw blade speed | 4800 rpm |

| 1 extraction connection | ø 140 mm |

| Compressed air connection | 6-10 bar |

| Wattage | 7.3 kW |

| Wattage with option 4SB | 10.7 kW |

| Mains connection | 3 x 400 V / 50 Hz |

*1 Option: 103 mm · *2 with 2 side holes Ø 9 mm, radius 30 mm · *3 Measurement standards and emission values according to EN 1870-14, measurement uncertainty allowance K = 4dB (A). (All data refers to CONTROL type 6224)

The following applies to all machines:

Efficient TRK dust extraction system significantly below 2 mg/m3. The system used must have an extraction performance of 20 m/s in order to meet the TRK specifications. (Vacuum approx. 1400 Pa. / COMPACT approx. 1470 Pa) at the connector in order to meet the TRK specifications.

Technical note:

Permissible ambient temperature min: + 5 °C / max. + 40 °C

Relative humidity: 19 - 95% without condensation

In case of mains fluctuations greater than +/- 10% of the nominal voltage, a voltage stabiliser must be installed at the place of use.

The technical specifications are approximate values.

We reserve the right to make changes due to further developments.

Dimensions in mm

| Type | L* | H | T1 free |

T2 Wall |

|---|---|---|---|---|

| 6224 | 7153 | 3035 | 1741 | 1361 |

| 6216 | 7153 | 2951 | 1700 | 1354 |

| 6168 | 7153 | 2477 | 1500 | 1312 |

| 5224 | 6153 | 3035 | 1741 | 1361 |

| 5216 | 6153 | 2951 | 1700 | 1354 |

| 5168 | 6153 | 2477 | 1500 | 1312 |

| 4224 | 5153 | 3035 | 1741 | 1361 |

| 4216 | 5153 | 2951 | 1700 | 1354 |

| 4168 | 5153 | 2477 | 1500 | 1312 |

* L = Total length of the machine, including control cabinet

Cutting area in mm

| Type | LS | HS vertical |

HS horizontal |

|---|---|---|---|

| 6224 | 5300 | 2240 | 2100 |

| 6216 | 5300 | 2160 | 2016 |

| 6168 | 5300 | 1680 | 1540 |

| 5224 | 4300 | 2240 | 2100 |

| 5216 | 4300 | 2160 | 2016 |

| 5168 | 4300 | 1680 | 1540 |

| 4224 | 3300 | 2240 | 2100 |

| 4216 | 3300 | 2160 | 2016 |

| 4168 | 3300 | 1680 | 1540 |

Configure STRIEBIG CONTROL

Simple, online and individually tailored to your needs: Configure your very own STRIEBIG CONTROL.