STRIEBIG ExpertCut – The 'PROFESSIONAL' version for the CONTROL and the STRIEBIG 4D

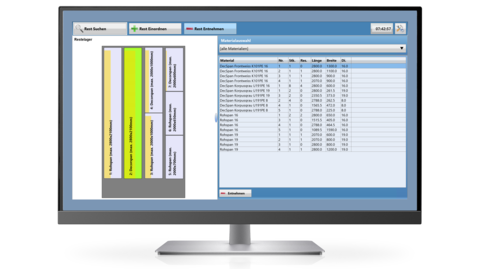

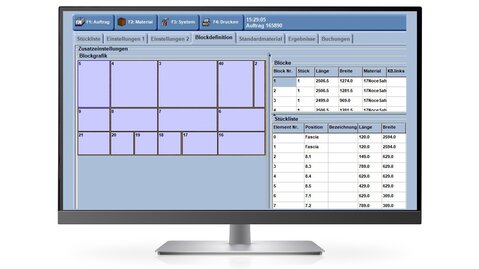

Simple and convenient: With ExpertCut you take on parts lists from conventional CAD or ERP systems and optimise them directly at the office workstation with the STRIEBIG cut optimisation software. You can also use the program to process and manage order, material and parts lists quickly and clearly.

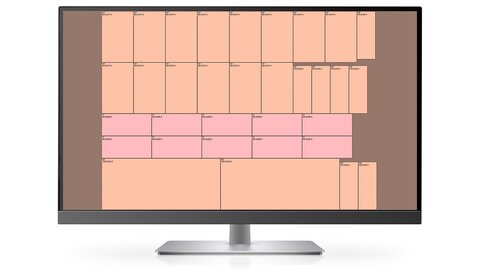

You transfer the cutting plan from your office workstation directly to the CONTROL or the STRIEBIG 4D. The intelligent visualisation on the 12" touch screen panel then guides the operator through the individual steps of the cutting process. With the CONTROL and STRIEBIG 4D, the operator uses the START button to position the saw unit and the length stop (EPS-X) and automatically moves to the defined dimensions. In combination with the panel lowering device (PAV) and the fully automatically programmable panel feeder (PPS), the STRIEBIG 4D even executes the entire horizontal and vertical transport of the workpiece automatically. This way you benefit from all the features ExpertCut has to offer.

Cut by cut, CONTROL and STRIEBIG 4D process your optimised cutting plan.The label printer prints the label for the identification of the cut element directly during the cutting process. And so high quality meets top efficiency.

The scope of supply of STRIEBIG ExpertCut includes:

- Electronic positioning system EPS-X

- Software package (operator guidance with STRIEBIG ExpertCut)

- Software license for 1 office workstation (network license)

- Label printer

- Connection possibility for network connection via LAN

- Operating instructions

- Paper holder

Available for the following STRIEBIG models

The ExpertCut option cannot be retrofitted. It must be ordered ex works.

ExpertCut: Software options

(can be retrofitted)