STRIEBIG OptiDivide – the retrofittable version

Easy to operate, efficient in use and easy to retrofit: STRIEBIG OptiDivide ensures a higher degree of automation in panel cutting. This makes work easier day in and day out. The system works completely independent of the machine control. OptiDivide can be retrofitted to many STRIEBIG models.

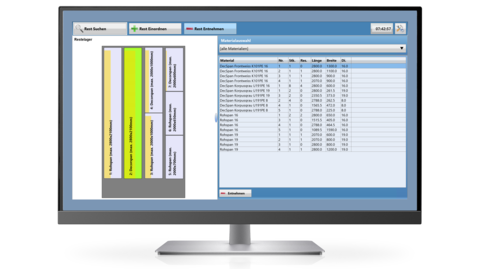

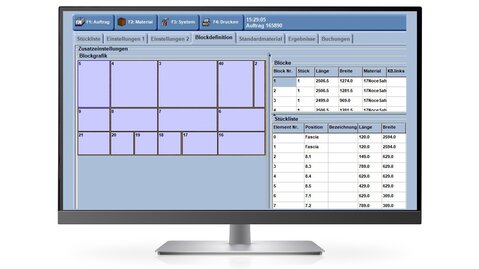

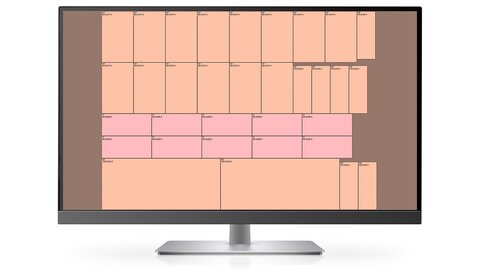

With STRIEBIG OptiDivide, you can transfer parts lists directly from standard ERP or CAD systems. The visualisation on the touch screen on the saw subsequently guides the operator through the individual work steps. The work steps carried out can be confirmed on the touch screen with a touch of the finger. The label printer prints the label for the identification of the cut element directly during the cutting process. Step by step, you can process even the most complex cuts in an optimised way by means of automated panel cutting.

The scope of supply of STRIEBIG OptiDivide includes:

- Compact aluminium housing with integrated 12" touch screen panel

- Label printer (installed and protected in the housing, operated by means of a drawer)

- Network connection via wireless network

- STRIEBIG cutting optimisation software package, incl. 1 network license for office workstation

- Power cable

- Mounting adapter for the corresponding STRIEBIG model

- Operating instructions

Applicable / Retrofittable

STRIEBIG OptiDivide can be retrofitted to the following STRIEBIG models.

OptiDivide: Software options

(can be retrofitted)