The original in vertical sawing technology

STRIEBIG – the original in vertical sawing technology. Invented by our company founder and pioneer Ludwig Striebig, it is the ideal combination of precision and economy. In many fields of application, STRIEBIG panel saws are the only possible cost-effective and space-saving solution for panel cutting.

More than

50.000

STRIEBIG vertical panel saws produced

Average of

15.400

operating hours per STRIEBIG life cycle

Cutting capacity of more than

1.000.000

sawn parts per STRIEBIG life cycle

STRIEBIG panel saws: maximum quality and durability

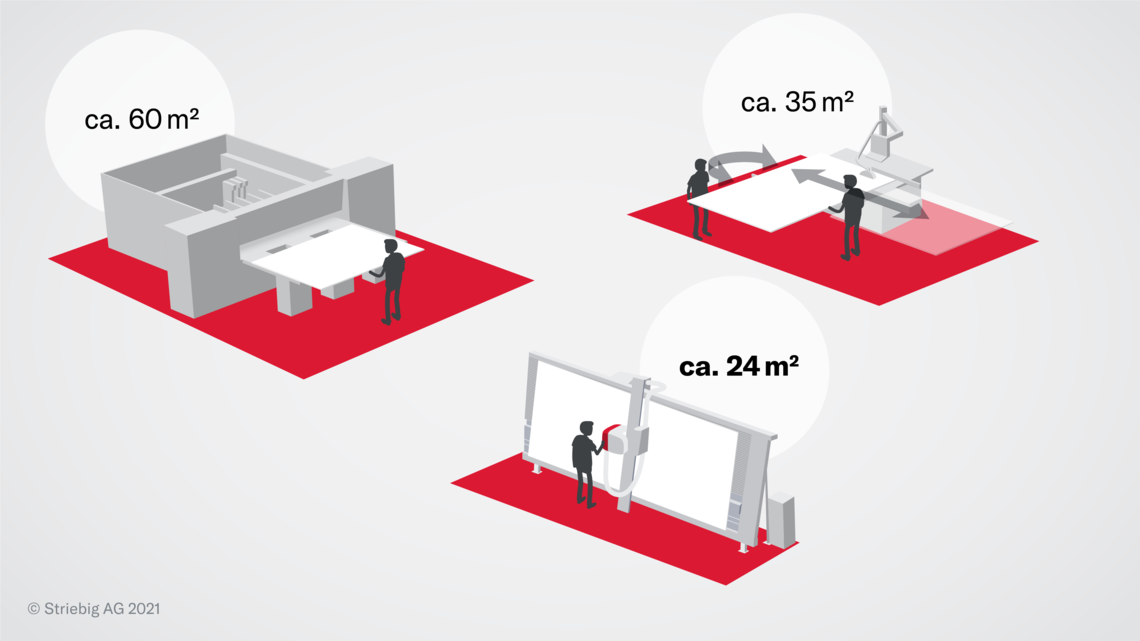

Minimum space requirement

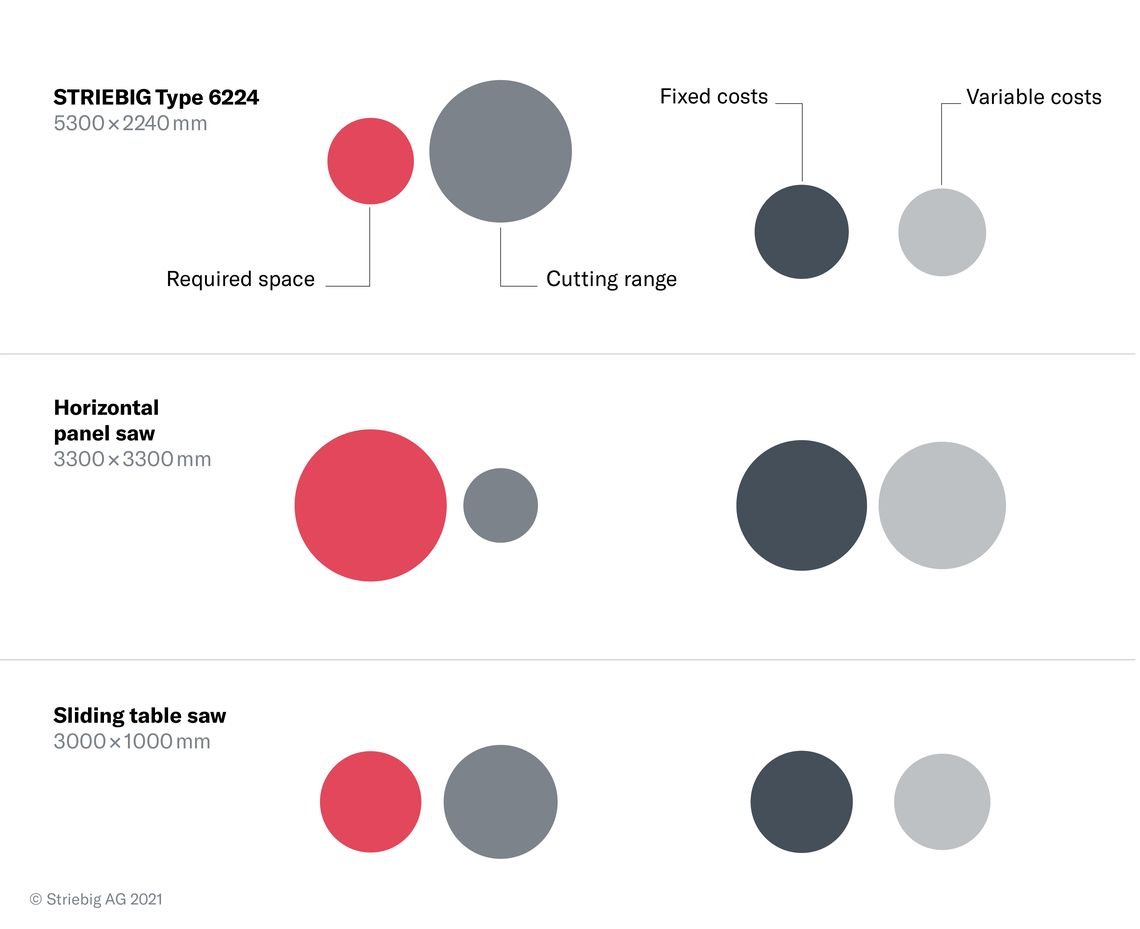

In contrast to a horizontal panel-sizing saw, the vertical STRIEBIG panel saw only requires about half the space. The area of a STRIEBIG including space in front of the machine for handling and feeding the panels is approximately 24 m2. A horizontal panel saw with a cutting range of 3300x3300 mm requires about 60 m including space for handling and feeding the panels2. If you also consider the advantage that panels up to 5300 mm in length can already be processed on a STRIEBIG in standard size, the vertical sawing technology shows its “space advantage” even more clearly.

Optimal value for money

Compared to other vertical panel saws, STRIEBIG saws already offer many accessories in the basic equipment. From the simple, hand-guided STRIEBIG to the high-end sawing centre with continuous data flow in production, the variety of vertical cutting technology is convincing in the various application areas of wood, plastic and composite panel processing. Low space requirement costs, low maintenance and service costs, as well as a high value retention of the investment further contribute to the optimal value for money of STRIEBIG panel saws.

Convincing customer satisfaction

Thanks to our decades-long leading market position, we have been able to continuously expand our customer base and enjoy above-average customer satisfaction. In cooperation with users and specialist trade partners, we are constantly further developing our machines. Thus our customers continuously benefit from more advantages of vertical sawing technology.

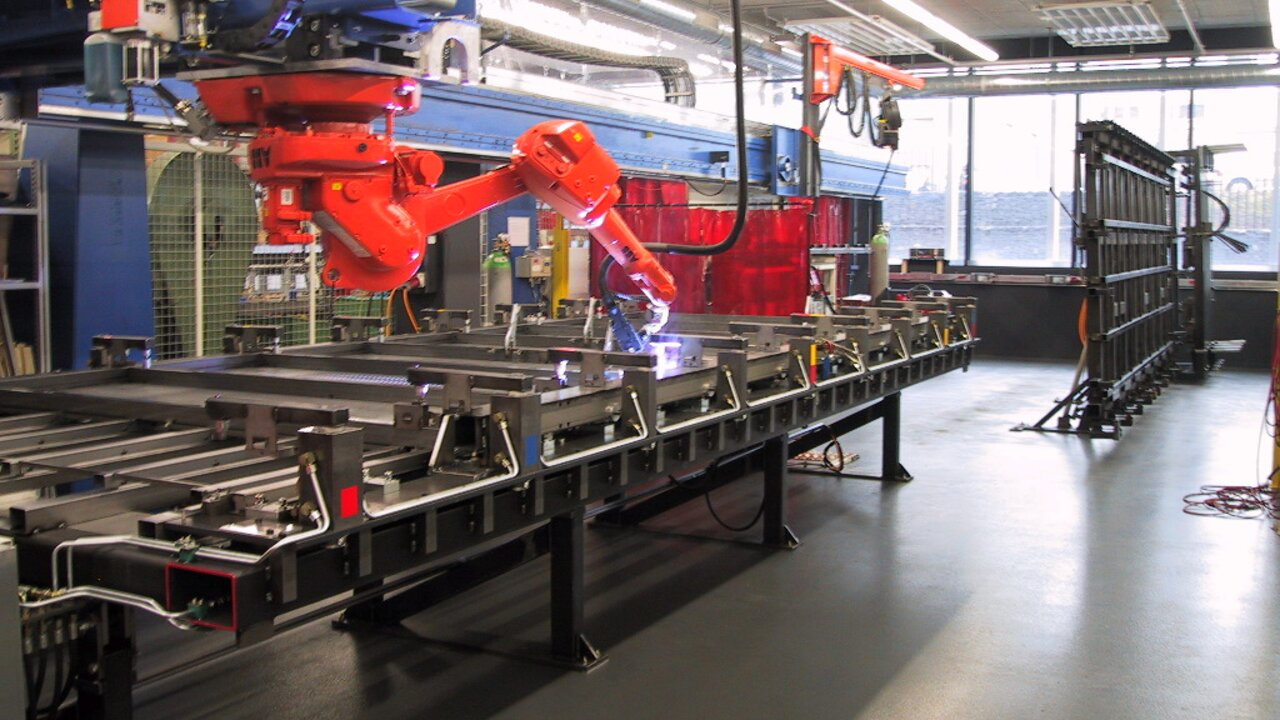

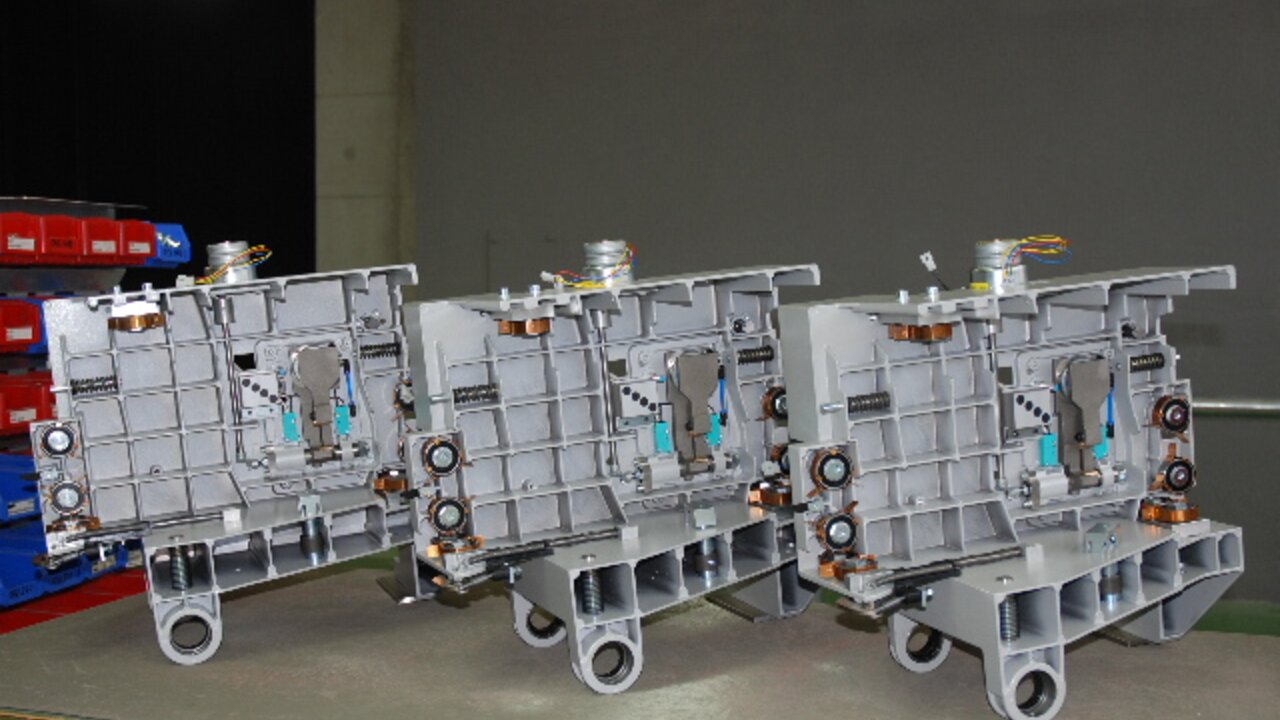

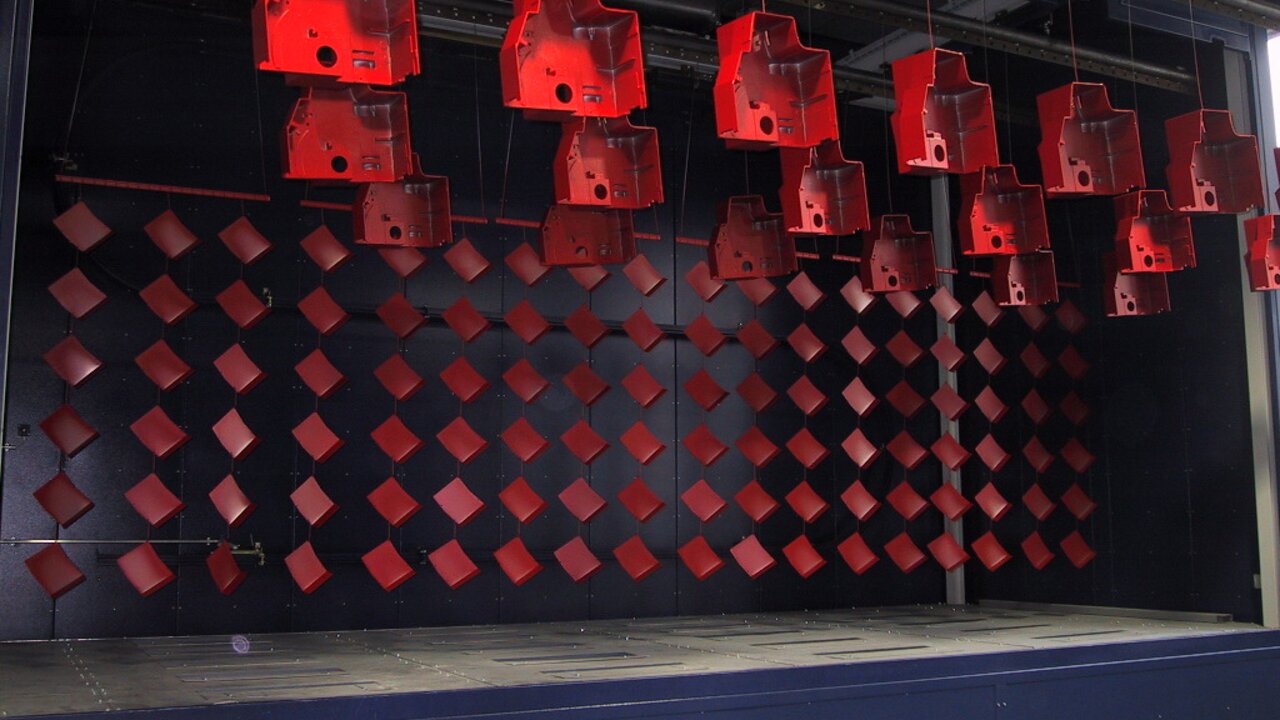

Produced in-house, Swiss-made in Lucerne

With enthusiasm and passion, the team at Striebig AG develops and produces the Swiss-made vertical panel saws at the production plant in Lucerne. We always keep an eye on the overall economic and ecological context of our activities. Our entire company is certified for its management systems in the areas of quality, environment, occupational health and safety and health protection.